SERVICES/

PRODUCTS

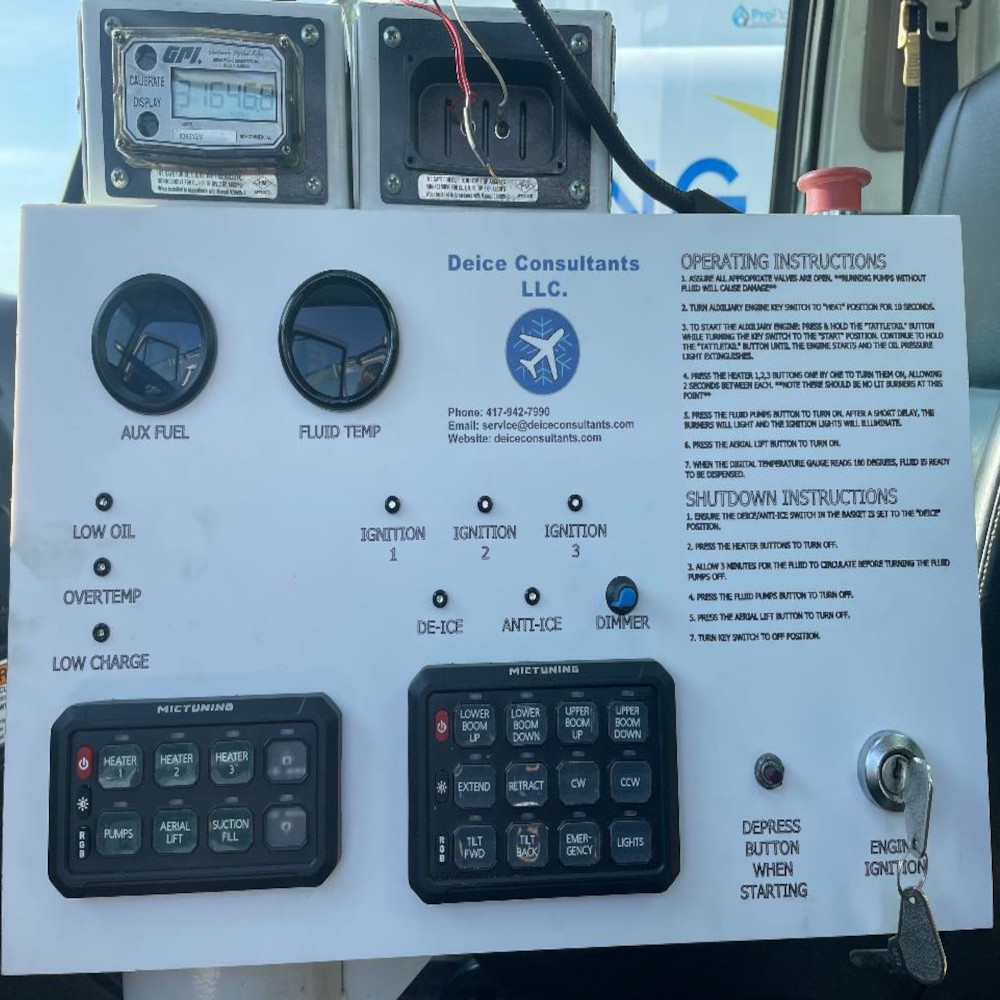

CONTROL PANEL PRODUCTS

TIER 1

The Tier 1 Control Panel Upgrade replaces outdated AC mechanical switches and lights, replacing them with DC latching push buttons and bright, adjustable LEDS for all pumps, heaters, and wipers. The upgrade provides a multitude of safety enhancements and allows for troubleshooting ease.

- Removes all 120V & 240V AC from Operators Station Control Panel. Replaced with safer DC components.

- Vastly reduced shock risk eliminating uninsulated terminal strips in outdated panel

- Protects equipment through use of latching switches. No more worries about turning off/on the engine and frying equipment with fluctuating frequency/voltage.

- Bright and adjustable LEDS ensures the operator knows exactly which equipment is operating.

- Enables the burners to use solid state ignition coils, which can provide much higher intensity spark to ensure combustion.

- Reduced interference using DC protects flow meters and other equipment from previous AC interference.

- Eliminates the majority of wires for components replaced in panel. The massive wire bundle is replaced with a single loomed harness with few wires.

- Readily available schematics and work instructions.

TIER 2

The Tier 2 Control Panel Upgrade replaces all items on the outdated AC Panel, save for the ignition and murphy switch. Panel components for the pumps, heaters, wipers, Aerial Lift switches, and engine lights are replaced with DC latching push buttons and bright, adjustable LEDS. Even the temp and fuel gauge are upgraded. This provides a multitude of safety enhancements and allows for troubleshooting ease.

- Removes all 120V & 240V AC from Operators Station Control Panel. Replaced with safer DC components.

- Vastly reduces amount of wires in panel by 90%.

- Eliminates shock risk by removing uninsulated terminal strips in outdated panel.

- Protects equipment through use of latching switches. No more worries about turning off/on the engine and frying equipment with fluctuating frequency/voltage.

- Bright and adjustable LEDS ensures the operator knows exactly which equipment is operating.

- New gauges for fuel and temp also are bright for easy viewing.

- Enables the burners to use solid state ignition coils, which can provide much higher intensity spark to ensure combustion.

- Reduced interference using DC protects flow meters and other equipment from previous AC interference.

- Eliminates the majority of wires for components replaced in panel. The massive wire bundle is replaced with a single loomed harness with few wires.

- Readily available schematics and work instructions.

TIER 3

The Tier 3 Control Panel Upgrade replaces the entire pedestal, replacing ALL components.

This new ergonomic design rids of the bulky and dangerous old panel. It encompasses all components of tier 1 and 2, including latching switches for the pumps, heaters, wipers, Aerial Lift, LEDs indicators for all, new gauges, new E-Stop button, new engine control, indicators for de-ice and anti-ice.

The upgrade provides the most safety enhancements of all tiers, and is the easiest to troubleshoot since all old components are replaced, and the wiring is minimized. This custom design allows for a platform to add enhanced options we are developing to your de-icer as needed.

- Removes all 120V & 240V AC from Operators Station Control Panel. Replaced with safer DC components.

- Vastly reduces amount of wires in panel by 90%.

- Eliminates shock risk by removing uninsulated terminal strips in outdated panel.

- Protects equipment through use of latching switches. No more worries about turning off/on the engine and frying equipment with fluctuating frequency/voltage.

- Bright and adjustable LEDS ensures the operator knows exactly which equipment is operating.

- New gauges for fuel and temp also are bright for easy viewing.

- Enables the burners to use solid state ignition coils, which can provide much higher intensity spark to ensure combustion.

- Reduced interference using DC protects flow meters and other equipment from previous AC interference.

- Eliminates the majority of wires for components replaced in panel. The massive wire bundle is replaced with a single loomed harness with few wires.

- Readily available schematics and work instructions.

SUMMER SERVICES

Ensure your equipment does not sit and rust during the off season. We provide summer services across the USA to prepare your Premier De-Icer trucks for the coming winter.

CUSTOM PROJECTS

We work with customers to design and install custom options that factory providers do not offer. Whether it be marker lights, led strip lights, custom sensors, decals, etc., we find solutions to fit your truck and airport style.

REPAIR SERVICES

We’re experience with repairing and troubleshooting all designs of Premier De-icer Trucks. Having issues? Call us today to see how to get your truck in great working condition.

Fill out our quick form with any inqueries you may have!

Whether its control panels or specialty projects, we will work with you to upgrade your Premier De-icer to the modern age.